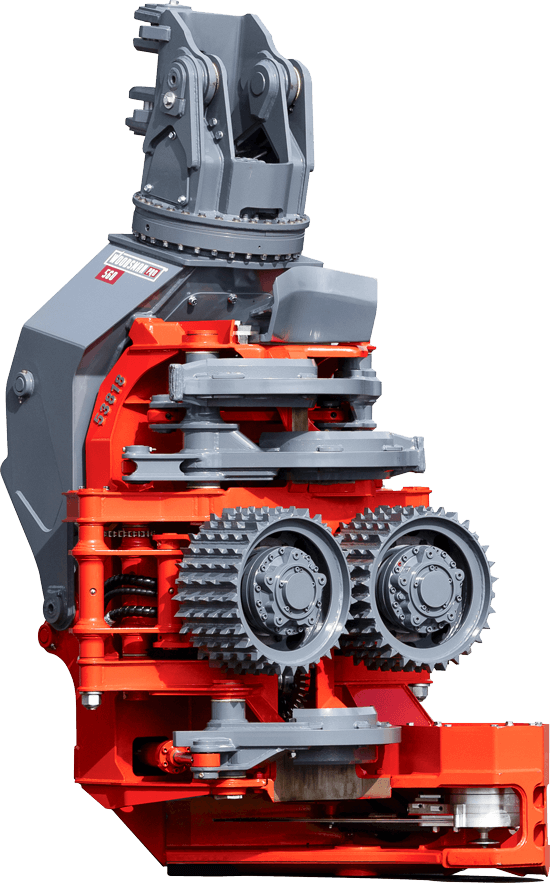

Compact solution for smaller wood and thinning

The Woodsman Pro 560, with its lighter weight and dimensions, is the ideal solution for thinning and harvesting smaller wood from base machines of 25-35 tonnes.

Featuring a maximum delimb opening of 599 mm, rapid feed speed and a powerful saw motor for efficient cutting. The three heavy-duty delimb arms and top floating knife combination provide excellent full delimb coverage (Ø510 mm). The arm shape is optimised to work with the top knife, ensuring full wrap-around knife contact against stems. Additionally, the lower knife enables the 560 to delimb right down to the saw cut, reducing wasted log handling.

Built with the same proprietary design and components as the 750 and 850 models, the 560 delivers the performance you’d expect from a Woodsman Pro harvester in a lighter, more compact package.

- Best-in-class single-pass delimbing

- Excellent full coverage delimbing capability or a machine of its size

- Equipped with Loggic control software, featuring a PDF map viewer with GPS

- Main saw automatic chain tensioning

- Unparalleled throughput and reduced reject rates

- Powerful 40 cc saw motor

- Lower delimb knife allows delimbing right to the saw cut, eliminating double handling of logs

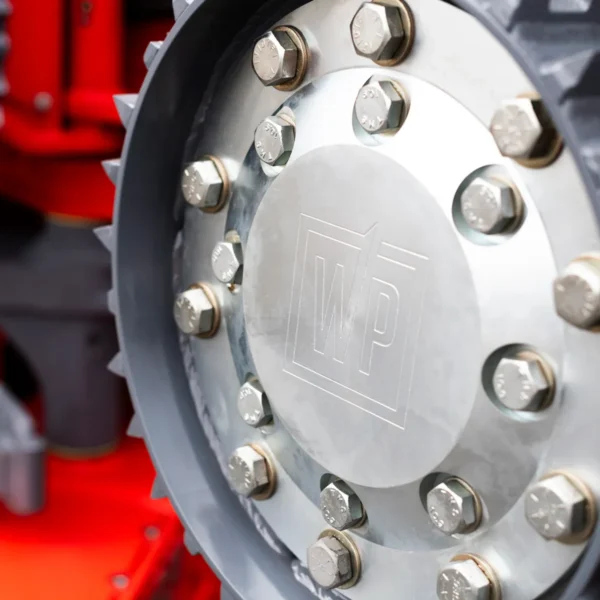

- Feed wheels feature reversible mounting to enable more even wear and prolong service life

- Downtime reduction due to:

- One-bolt replaceable delimb knife insert system, patented in over 25 countries

- Replaceable bolt-in belly wear plates

- Top floating delimb knife and keepers feature replaceable wear pads

- Reversible saw sprocket

- Hose-free saw swing arm

- Dual diameter sensors for increased diameter accuracy and reliability

- 360-degree continuous rotation for manoeuvrability

- On-board fault diagnosis for head and base machine

- Fabricated steel control valve bonnets providing easy access to the main control valve and critical maintenance areas

- Large range of service exchange parts to minimise downtime

- Knuckle design allows for a large swing arc and excellent grease point access

- Reliable, tried and tested components used in our 750 and 850 models, including cylinders measuring wheel assembly, saw unit, and feed wheel design

- Nationwide service network ensuring easy access to expert service and support.

Dimensions

- Weight (excl. knuckle): 2860 kg (6305 lb)

- Max harvest tilt: 145°

- Rotation: Continuous 360°

Feeding

- Max force @ 350 bar: 29 kN (6519.4 lbf)

- Feed speed @ 350 I/m: 6.3 m/s (20.7 ft/s)

Delimb

- Max knife opening: 599 mm (23.6 in)

- Min stem diameter: Ø40 mm (1.6 in)

- Max full cov. delimbing dia: Ø510 mm (Ø20.1 in)

- Knives: 3x delimb, 1x floating top, 1x fixed lower

Main Saw

- Max saw cut: Ø640 mm (Ø25.2 in)

- Bar length: 32, 34 in

- Chain pitch: 0.75 in

- FEATURES

- Best-in-class single-pass delimbing

- Excellent full coverage delimbing capability or a machine of its size

- Equipped with Loggic control software, featuring a PDF map viewer with GPS

- Main saw automatic chain tensioning

- Unparalleled throughput and reduced reject rates

- Powerful 40 cc saw motor

- Lower delimb knife allows delimbing right to the saw cut, eliminating double handling of logs

- Feed wheels feature reversible mounting to enable more even wear and prolong service life

- Downtime reduction due to:

- One-bolt replaceable delimb knife insert system, patented in over 25 countries

- Replaceable bolt-in belly wear plates

- Top floating delimb knife and keepers feature replaceable wear pads

- Reversible saw sprocket

- Hose-free saw swing arm

- Dual diameter sensors for increased diameter accuracy and reliability

- 360-degree continuous rotation for manoeuvrability

- On-board fault diagnosis for head and base machine

- Fabricated steel control valve bonnets providing easy access to the main control valve and critical maintenance areas

- Large range of service exchange parts to minimise downtime

- Knuckle design allows for a large swing arc and excellent grease point access

- Reliable, tried and tested components used in our 750 and 850 models, including cylinders measuring wheel assembly, saw unit, and feed wheel design

- Nationwide service network ensuring easy access to expert service and support.

- SPECS

Dimensions

- Weight (excl. knuckle): 2860 kg (6305 lb)

- Max harvest tilt: 145°

- Rotation: Continuous 360°

Feeding

- Max force @ 350 bar: 29 kN (6519.4 lbf)

- Feed speed @ 350 I/m: 6.3 m/s (20.7 ft/s)

Delimb

- Max knife opening: 599 mm (23.6 in)

- Min stem diameter: Ø40 mm (1.6 in)

- Max full cov. delimbing dia: Ø510 mm (Ø20.1 in)

- Knives: 3x delimb, 1x floating top, 1x fixed lower

Main Saw

- Max saw cut: Ø640 mm (Ø25.2 in)

- Bar length: 32, 34 in

- Chain pitch: 0.75 in

- DOWNLOAD