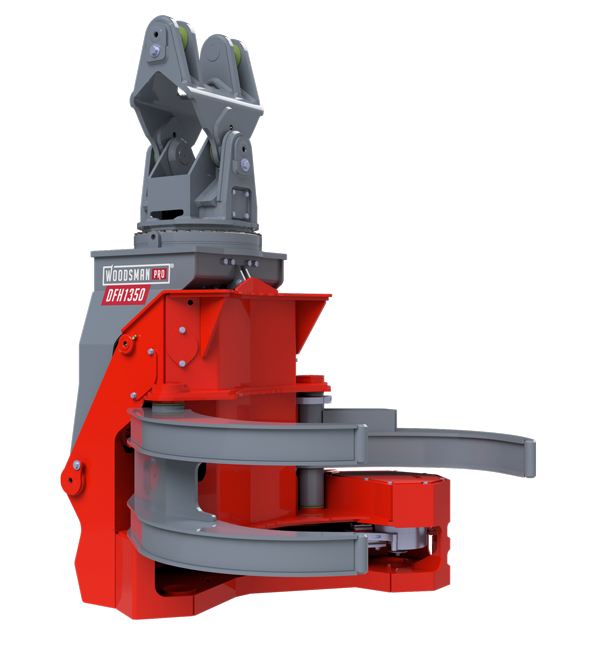

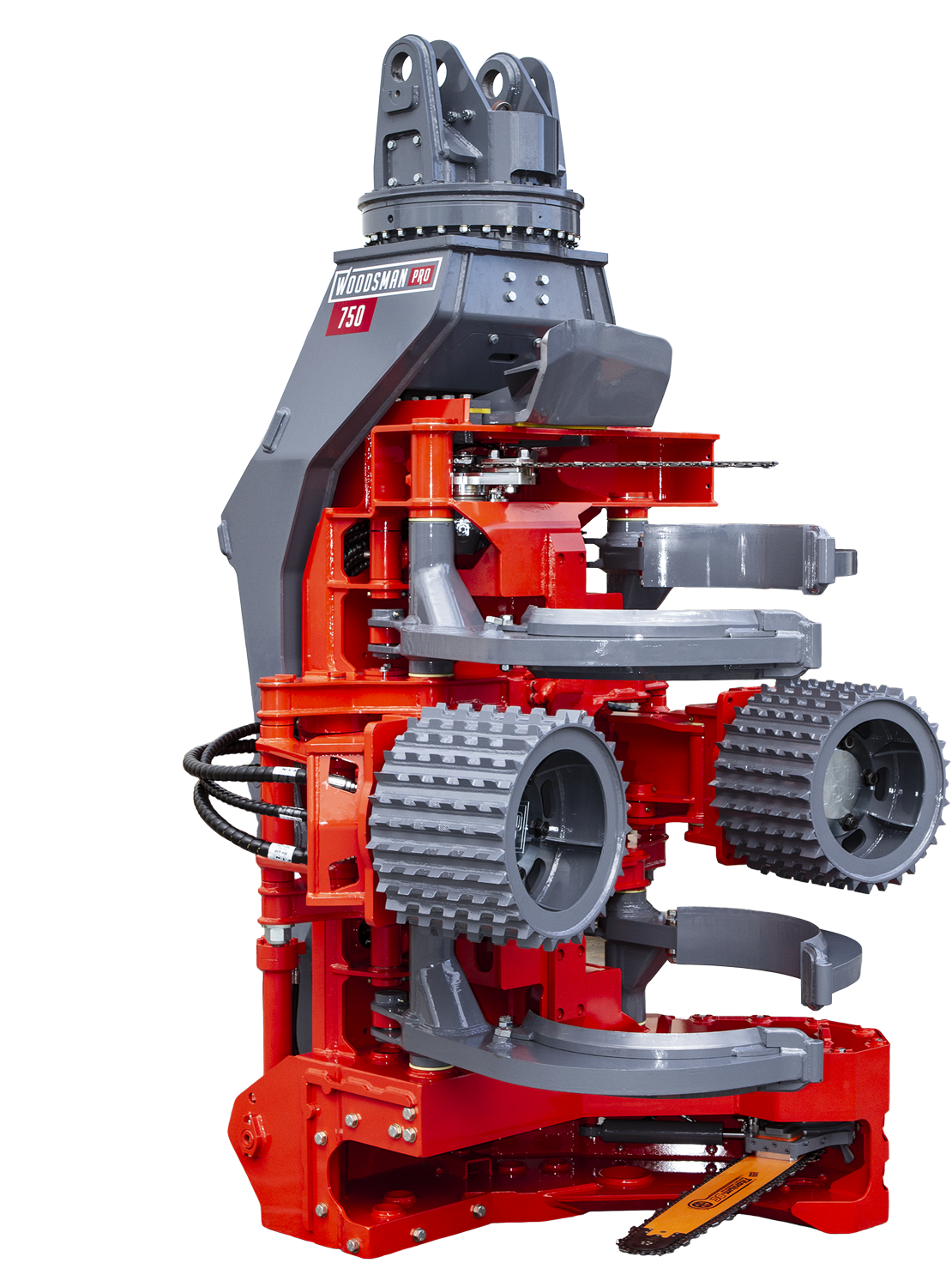

Engineering Services Rotorua Ltd designs and manufactures each and every Woodsman Pro product. We supply a state-of-the-art control system developed in-house which specifically suits our own equipment, your local resource, and your individual requirements.

We modify and convert machines for harvesting and processing; install, test and commission the overall package; and will train your operators to get the best results from both a productivity and safety point of view.

Why choose

Woodsman Pro

- Simple control system – operators quickly learn how to make the best value cutting decisions.

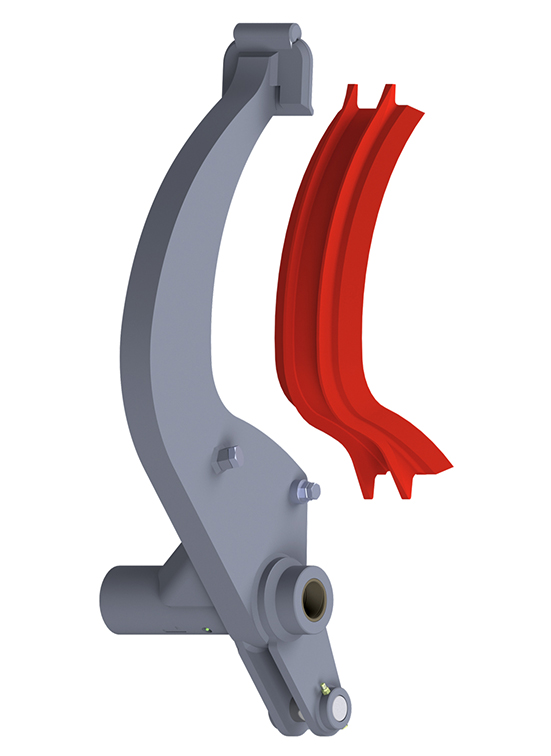

- Reliable and robust structure – our solid design means minimal component failures and a long reliable life (recommended maintenance practices must be followed).

- Internally developed and supported control system – this can be easily customised and improved to meet the changing requirements of forest managers, contractors and operators.

- Future upgradeability – new enhancements can be added to existing machines so you can keep up with new functionality and features as they’re developed.

- Clean single pass delimbing – for fast and efficient log making.

- Developed for New Zealand – designed to suit local conditions including log size and species.

- Highly skilled and trained technicians – to help you maximise the value of your forest harvest.

- Personal relationships – you can easily get hold of us when you need to.

- Exchange refurbished parts – maintain optimum performance and minimise on-going operational costs for replacing components as they wear.

- Maintenance and operation training – improve overall reliability, performance and profitability by letting us fully train your operators.

- Manufacturing and installation completed in-house – all base machine forestry conversions, head installations and testing is carried out-in house by our engineering and hydraulic/electrical commissioning teams.

- Superior service and field support – our field service technicians provide prompt back-up services and have access to our well-stocked spare parts department.

Please note, specifications or functionality were correct at the time of publishing but may be subject to change as necessary and without notice.

Engineering Services Rotorua Ltd designs and manufactures each and every Woodsman Pro product.

We supply a control system developed in-house which specifically suits our own equipment, your local resource, and your individual requirements.

We modify and convert machines for harvesting and processing; install, test and commission the overall package; and will train your operators to get the best results from both a productivity and safety point of view.